Best Available Techniques

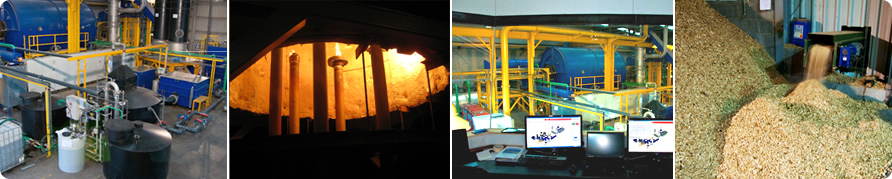

Built upon several years of research and development, Stein Pyrolysis Units (SPU’s and VSPU’s) generate energy from waste or biofuels with efficiencies that are unobtainable from previous thermal treatment systems.

Traditional pyrolysis systems have been unable to achieve robust operational solutions that overcome issues such as fouling, over cracking of fuel, under cracking of fuel, low calorific value gas, air elimination and component life (particularly the retort). The SPU’s by design overcome these obstacles and can achieve in excess of 80% combined heat and power efficiencies, virtually zero waste, high calorific value gas yields and abundant high grade heat.

Best Available Techniques (BAT) Key Indicators

1) Fuel

- Fuel flexible system with diverse applications that incorporate multiple opportunities for revenue generation or savings across various industries.

- Fuel is prepared to an acceptance criteria of 15-20mm particle size and moisture content of 5% ± 2.5%. Inert and recyclable material is removed from feedstock prior to input into the pure pyrolysis system.

2) Conversion Process

- Continuous pure pyrolysis.

- Char used in process to deliver maximum efficiencies

3) Gas Quality

- Thermochemical reaction, no combustion, therefore no products of combustion or dioxins created in syngas.

- Gas scrubbing system to remove contaminants prior to use on standard syngas engines.

- High calorific value syngas (18Mj/Nm3 – Woodchip, 25Mj/Nm3 – SRF) which is 100% distributed to the engine. Low levels of Hydrogen and Nitrogen to ensure optimum engine performance across the gas spectrum.

- High gas conversion yields ensuring maximum syngas evolution from the fuel feedstock coupled to an engine; the fuel, therefore, generates maximum electrical yield and thus an accelerated return on investment.

4) Emissions

- Low emissions due to use of char and automated control on Oxygen levels within the system

- Zero detectable dioxins

5) Highly Automated

- Simple operation and process control that is fully automated with SCADA software and trending of critical parameters.

6) Minimal Parasitic Load

- Electrical parasitic load is minimised by the use of control logic and energy efficient variable speed drives on all motors.

7) Flexibility

- Deliberate compact design ensures good use of client-allocated space and is scalable to optimise client’s available waste streams. The scalable nature increases its location flexibility and minimises visual disruption to the surrounding environment.

8 ) Efficiency

- Efficiencies are achieved through use of char and by automatic control of critical parameters on the system. Overall combined heat and power efficiencies of greater than 80% are achievable and 700oC of high grade heat is available for clients use.

9) Compliant with EU Policy & Directives

- Waste-to-energy provides a sustainable method of managing residual waste and is consequently a preferred waste management strategy. SPU’s pure pyrolysis system is compliant with the Waste Incineration Directive (WID) and its successor the Industrial Emissions Directive (IED) and can assist with meeting targets for renewable energy generation and landfill diversion as outlined in other EU Directives.

10) Attractive Financial Returns

- SPU’s technology is competitively priced on a cost per MW basis. By design, the system is automated to minimise maintenance and reduce labour overheads. This ensures the system is capable of efficiently converting waste products into electrical and thermal energy, thus generating an attractive return on investment.

11) Fuel Flexibility

- Each unit will be customised to accommodate site and fuel requirements. Stein Pyrolysis Units accept a wide variety of waste and biomass material:

Waste to Energy Materials

- Municipal solid waste (MSW), and miscellaneous, pre-sorted industrial waste

- Commercial and industrial waste

- Agricultural waste such as chicken litter,

- Organic residues from crops

- Abattoir and food processing waste

- Sewage sludge (animal slurries and urban wastes)

- Clinical waste

- Tyres

- Plastics

- Lubricants

Biomass to Energy Materials

- Timber and crops (either specifically grown for the process, or waste from existing industries)

- Miscanthus

- Forestry waste

- Straw

- Willow

- Biofuels / Biofuel production

- Peat (not strictly bio)

- Lignite (coal and peat, not strictly bio)

- Torrefraction

- Animal by-products (feathers, meat and bone meal, offal etc.)

- Sewage sludge, Chicken litter